It’s About Unique People Providing Creative Packaging Solutions

California Box-our history of corrugated box manufacturing

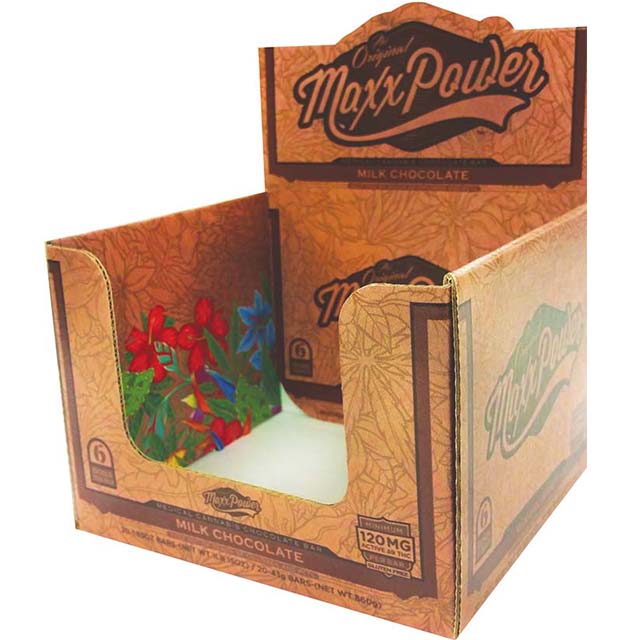

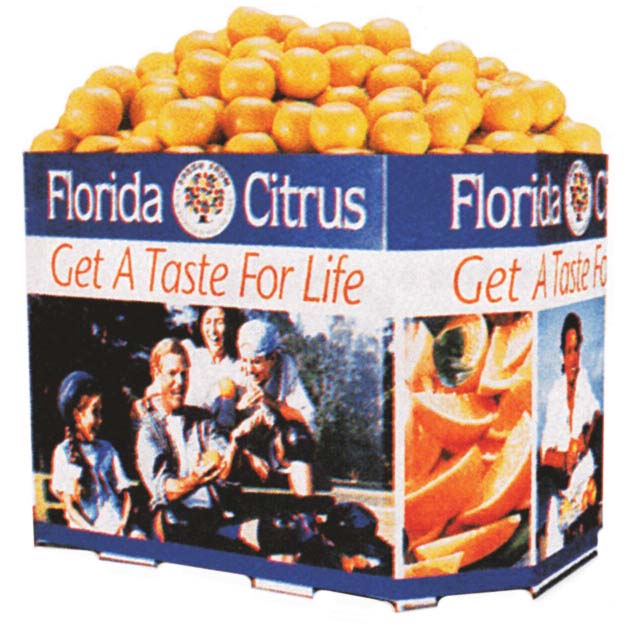

The CalBox Group sells every style of box and POP display to industries as varied as high-tech, specialty foods, sporting goods, toys, beverages, furniture, automotive, and more

As a Box Maker - We Provide Choices of:

- White Boxes

- Multi-Depth Boxes

- Flat Boxes

- Multi-Depth Boxes

- Long Boxes

- Printed Boxes

- And More

Our Promise: The CalBox Group will consistently meet and exceed our customers’ expectations with value added manufacturing and J.I.T. Logistics.

We are part of a Better Solution.

Whatever your needs are, whatever you can imagine, when packaging matters, the calBox group will find the eye-catching solution.

We have the leadership, experience, & capabilities to meet evolving goals to sell your brand's story.

The future success of your business is what ultimately determines the degree of success of our business.

It's About Competitive Advantages

Our teams have the necessary desire and experience in service and production to handle the special needs of our customers.

A combined workforce of over 400 talented employees providing the best design, sales service, production and logistics capabilities – always at competitive prices.

Owning over 700,000 sq.ft. of buildings. CalBox leases warehouses in Mexico so we can deliver most packaging products on demand.

Our alliances, two world class corrugators and a network of five large modern converting facilities, we assure our customers production continuity while meeting their expectations and our high standards.

280 to 300 pounds of fruit

It's About Solutions:

It’s about being able to provide diverse packaging solutions from our creative and professional teams.

CalBox Group

We are part of a Better Solution.