Corrugated Box Styles

Custom Corrugated Boxes

It’s practical, useful, economical, renewable and recyclable. It’s lightweight, routinely custom designed and provides unparalleled merchandising power.

It offers unlimited possibilities for design and merchandising appeal.

Corrugated boxes protect all kinds of products in shipping from manufacture, to point of sale, to their ultimate destination at home, office or any-where. It offers unlimited possibilities for design and merchandising appeal.

- And More

The future success of your business is what ultimately determines the degree of success of our business.

- Boxes of all sizes, glued, taped or stitched

- High Graphic Printing up to 4 colors

- Digital printer for photographic print quality

- Short or medium sized orders are our niche

- Die cutting: Rotary and Flat, any size

- Assembly of partitions, boxes and displays

- RTE Reverse Tuck Ends

- RSC Regular Slotted Container

- HSC Half Slotted Container

- FOL Full Over Flap

- OPF One Piece Folder

- FPF Five Panel Folder

- RSTT Roll Side Tuck Top

- RETT Roll End Tuck Top (mailer)

- DS Double Side Box

- DST Design Style Tray

- CSSC (AFM) Center Special Slot

- POL (OSC) Overlap Slot Container

- VD Vari-Depth Folders or Boxes

- FTHS Full Telescope Half Slot Box

- GAYLORDS Bulk Cargo Containers

- Auto Lock Bottom Boxes

- 4-Corner Trays

- Displays of all styles

- Corrugated packaging

- W5C

- V3C

- Michelman Coating

- #1 White

- #2, #3 White

- Solid Ink Coverage

- GCMI & PMS Ink

- Specialty boards, coatings and Ink

- Anti Rub Ink

- Anti Stat (ESD)

- WRA

- Waxed

- N & F Flutes

- Triple Wall

- Fire Retardant

- Rail Classification Alt Rule 41 (ECT)

- Rail Classification Rule 41 (Mullen)

- Truck Classification Rules (NMFC)

- Air Cargo Rules

- UPS Regulations

- Federal and Environmental Specs

- Hazardous Material Packaging (DOT) (UN)

- Military Specs

- Parcel Post Regulations

- ISO 9001-2015 Quality Certifications

- NAFTA Quality Certification (We ship into Mexico)

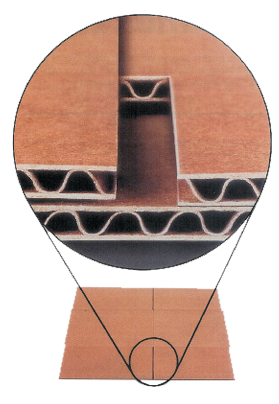

No High-Low or Delaminated Flutes

CalBox proven quality boxes are supplied in plain Kraft, coated, or white. The top liners are made from recycled or virgin paper. Laboratory tests results meet or exceed competitors’ products.

Finding quality corrugated board is the first step to developing your perfect corrugated box style.

Custom Corrugated Box Styles

It’s practical, useful, economical, renewable and recyclable. It’s lightweight, routinely custom designed and provides unparalleled ...

Slotted Corrugated Boxes

The most common corrugated box style, with little manufacturing waste, is a highly efficient design with many applications...

Corrugated Mailer Boxes

Designed to wrap around the product, corrugated mailer boxes provide extra protection for small objects and rough ...

CalBox Group

We are part of a Better Solution.