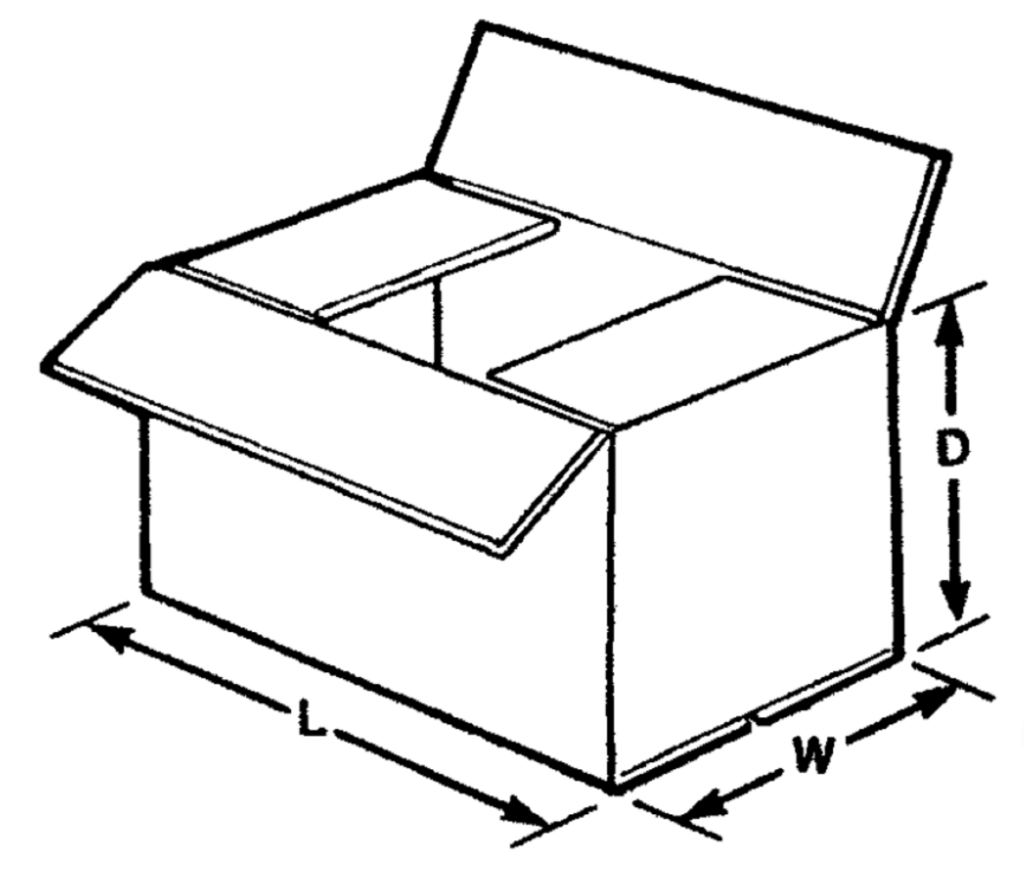

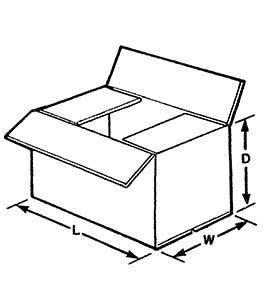

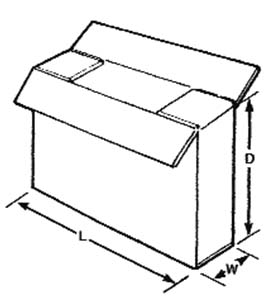

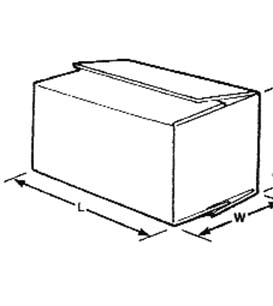

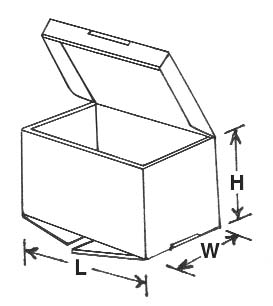

Slotted Corrugated Boxes

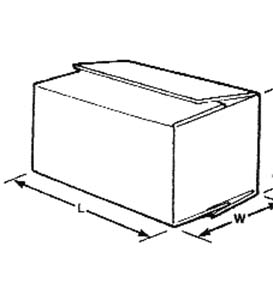

The most common corrugated box style, with little manufacturing waste, is a highly efficient design with many applications.

As a corrugated box manufacturer, CalBox can design custom quality corrugated boxes that allow the flaps to fold better with no cracked scores, as well as giving the box 30 to 50% more stacking strength.

The future success of your business is what ultimately determines the degree of success of our business.

- Custom corrugated boxes, all sizes, materials and styles

- Stock Boxes

- Boxes, all sizes - glued, taped, or stitched

- One-piece 2-color boxes up to 100” x 212”

- Tear Strip Options

- Graphic/color packaging

- Made from 200# test

- #3 White exterior

- V3c and W5c government board or boxes

- And More

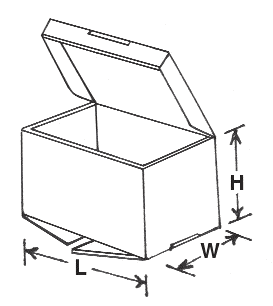

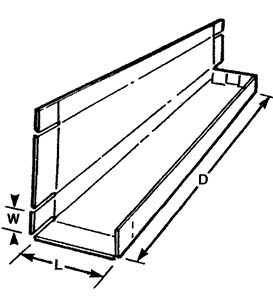

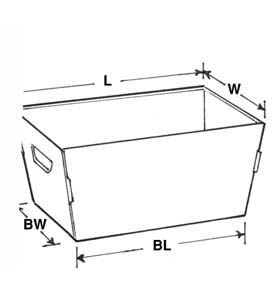

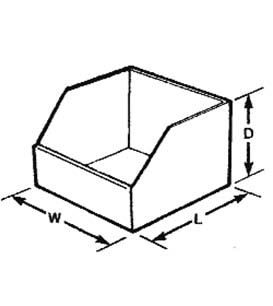

Custom Corrugated Box Styles

It’s practical, useful, economical, renewable and recyclable. It’s lightweight, routinely custom designed and provides unparalleled ...

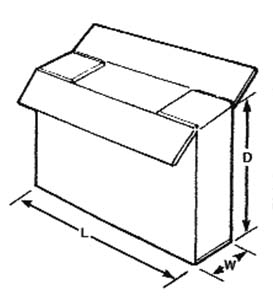

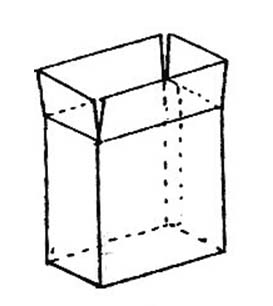

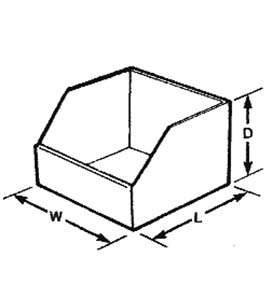

Slotted Corrugated Boxes

The most common corrugated box style, with little manufacturing waste, is a highly efficient design with many applications...

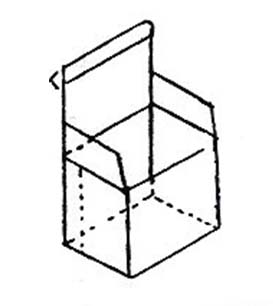

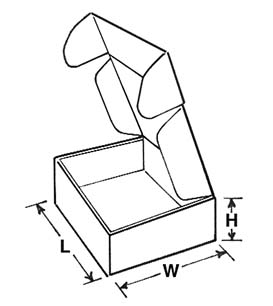

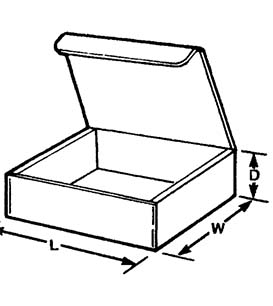

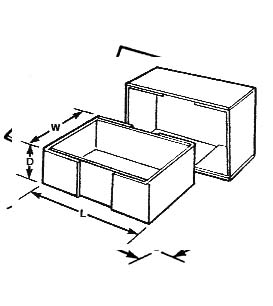

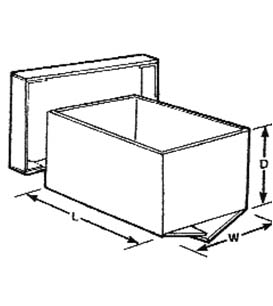

Corrugated Mailer Boxes

Designed to wrap around the product, corrugated mailer boxes provide extra protection for small objects and rough ...

CalBox Group

We are part of a Better Solution.