Advantages of our Manufacturing and Modern Corrugator

CB Sheets, a division of CalBox, manufacturers strong, versital corrugated sheets for boxes & displays

“Our superior board grades, extensive technical know-how, and the high degree of production precision, improves our sheet basis weight, smoothness, it’s consistent moisture profile, caliper control, porosity and brightness.”

John Widera, Chairman, CalBox Group

Corrugators in Action

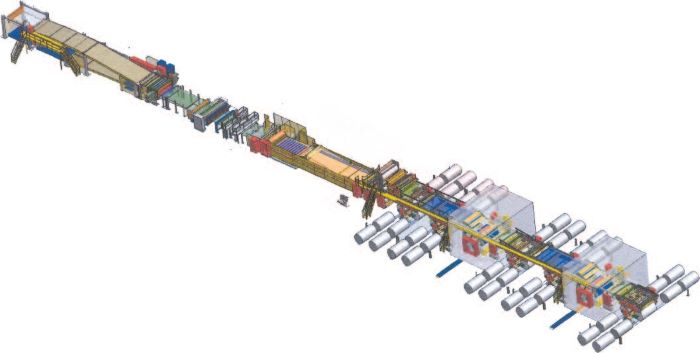

Our state-or-th-art, 400-foot long computer operated corrugators form heated medium into flutes, then apply glue to the tips of the flutes and combine the rolls of linerboard into corrugated sheets.

The continuous running 1,000 feet per minute process produces stronger board with less water and control of warp.

We can run short orders, almost as fast as long run orders due to our instant order change capability

CalBox l & ll state-of-the-art corrugator

turning 3 rolls of paper container board sheets

turning 3 rolls of paper container board sheets

CalBox l & ll state-of-the-art corrugator

turning 3 rolls of paper container board sheets

turning 3 rolls of paper container board sheets

CalBox l & ll state-of-the-art corrugator

turning 3 rolls of paper container board sheets

turning 3 rolls of paper container board sheets

Some insight in to CB l and CB II’s Corrugator

- Our state-of-the-art 98” BHS corrugator insures no high-low or misformed flutes, no wash boarding, and almost no cracked scores. We are a single source (we do not buy on the open market) using the best containerboard (paper) available. The corrugator does not stop or slow down preventing waste or warp when doing an order change. It prevents delaminization of sheet.

- With our own fast set-up corrugator with data collection, CB Sheets has advantages of consistent on-time deliveries. Warehousing over a long time is expensive and increases warp and less integrity (stacking strength) of the box

- We will not compete in mill runs, whenever possible. Why? We do not sell commodities by the ton or market share. We sell on value! Our well earned reputation for being on time with quality, is extremely important to us.

- Almost all of our containerboard is recycled; even the waste from our facilities is recycled. For special orders (virgin) Kraft (30% recycled) is available (Mullen grade).

-

Our 98" corrugator can run a liner instead of using a weak medium. Few corrugators in our market have the proven technology to run 3 liners for single wall. In other words, we can increase the strength of the medium (and box) by running balanced liners such as 35-35-35. Liners and medium combined on various corrugators have widely different board strength (ECT) performances. Consider different corrugating technology with age of other corrugators in our market, a variation of forty (40) percent is not urprising.

(per R. Young, AICC expert)

In-House Corrugators

-

Two state-of-the-art corrugators provide more proven benefits for production and lower the cost of containerboard to make boxes.

Computerized controls for our 98” wide , 400 foot long Corrugator in So Cal plant

In-House Corrugators

-

Two state-of-the-art corrugators provide more proven benefits for production and lower the cost of containerboard to make boxes.

Computerized controls for our 98” wide , 400 foot long Corrugator in So Cal plant

The “wet section” of our Corrugator.

- “Around 70 - 80% of our sheet prices is cost of goods sold (COGS). The roll stock is purchased by tonnage and in MSF (thousand square feet) – the language of the corrugators and converters understand best.”

“The reality is that innovation has made it possible to make container board and boxes water and humidity resistant, protected against harmful bacteria and trackable throughout their journey with printable nano technology,”

Chris Widera, CEO.

Streamlining CB Sheets

- At CB Sheets our corrugator scheduling system software reduces side trim waste and minimize wet-end roll changes in real time. It offers suggestions on which paper roll sizes optimizes our efficiencies. The scheduling score boards provide instant results such as least width changes, least trim, shortest setup, least order splits, total splits, lineal per width and utilization

- Once an order is scheduled, we have access to follow it until it has been delivered to our CB l or CB ll sister plants. Both of our plants have location barcodes placed on the ceiling so that when sheets are received by our forklift drivers, who have computers and handheld scanners on their forklifts, we can easily locate them in our warehouse.

CalBox Group

We are part of a Better Solution.